It all starts with polypropylene granules

The principal component of PRIPLAK® is polypropylene in the form of granules. Before this material was invented, the gaseous residue from oil was burned at a pure loss. It is now recovered to produce polypropylene, thus helping limit pollution of the atmosphere.

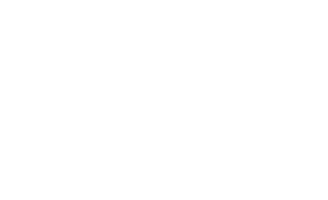

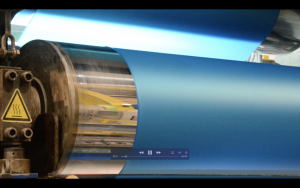

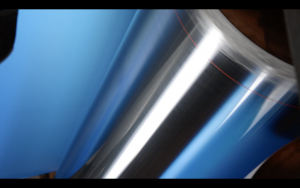

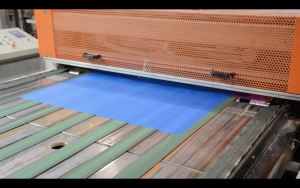

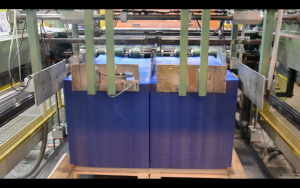

The granules are fed into an extruder where they are melted, mixed and homogenised. The paste obtained then passes between cylinders where it is flattened, then cooled and cut into sheets.